Several of the pads are for unnecessary components, which is why they're not filled in.

Sunday, November 8, 2009

FreePoint SMT Video

Sunday, August 2, 2009

Rocket Chute Deployment

I had him check digikey.com for a cheap altimeter, and we found one for $7, but the lead time was too long. He's moving pretty soon, so we needed an immediate solution. I decided that we could use an accelerometer, and when it reads 0-Gs on the vertical axis, we'd know it was free-falling. (or had ended acceleration)

We set up a timer that would deploy the parachute a given time after the acceleration ends.

The red and blue wires arm the device. These get twisted together after you get the rocket set up. so it won't go off unexpectedly. The device also monitors the nichrome ignition wires. If one of the wires gets broken, you can tell from the LED indicators on the bottom.

Here's the underside of the board. I drew it up in EAGLE and etched it in the shop at work. You can see it's a little on the hablich side, needs a dose of alcohol and it could also use a small redesign. I noticed after I got the software running that a couple of the outputs were configured wrong in the hardware. If I ever make a V2.0, it'll be a little more attractive.

Here's the underside of the board. I drew it up in EAGLE and etched it in the shop at work. You can see it's a little on the hablich side, needs a dose of alcohol and it could also use a small redesign. I noticed after I got the software running that a couple of the outputs were configured wrong in the hardware. If I ever make a V2.0, it'll be a little more attractive.Hopefully we'll be able to test it out next week after I get back from Mexico.

Friday, May 29, 2009

Agitation

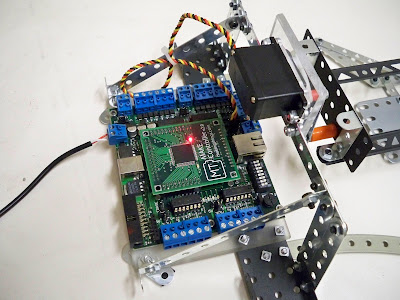

You can see that this project uses the make controller as well as an erector set. I used a HiTec 645MG servo for the agitation.

I didn't have anything to etch at the moment, so the video shows the tub with Mountain Dew in it instead. Maybe that would be good for etching designs in teeth...

As you can see, the servo oscillates above and below the horizontal. This ensures that the acid flows both ways.

I made a circuit board for a device we're calling FreePoint. This is the prototype design that's made to plug in as an arduino shield. The final version will be standalone.

Monday, January 26, 2009

Dr. Claw First Run

Now I've got to write some extra-custom software that will allow me to navigate to coordinates and manipulate objects. I also plan to integrate the Wii remote after that using the C# library. Shouldn't be too tough.

You'll notice that the shoulder joint isn't running yet. I'll be adding a geared stepper motor to the base (which already has the gears integrated as shown in a previous blog). I'll also need to make the shoulder a bit sturdier and add a servo reverser before that joint works.

The music is a new song I'm working on with Fuzil.

Saturday, January 24, 2009

Dr. Claw: Hand of Destruction

... I mean even better looking than this...

... I mean even better looking than this...So here's what I made:

It's a robotic arm. I modeled it off an industrial robotic arm with 5 degrees of motion. It has base rotation, shoulder, elbow, and wrist rotate as well as wrist tilt. Also has a sweet lookin' claw attached to the end.

Here's a shot of the claw in full vertical extension. You can see that I'm using dual servos at each joint. This will allow me to have plenty of strength to move the (heavy) metal Meccano pieces as well as whatever's in the claw at the time.

Build Details:

The above picture is the rotational base. It is purely Meccano, and rotates quite well. I set it up so that I'll be able to drive it with a stepper motor later on via the gear on the left. The stepper will allow me to drive it to a specific angle for precise movement. I really had to put on my thinking cap to come up with the design above.

Here's the stepper I'll be using:

In order to actuate the arm, I had to attach the servo horns somehow. I made servo links from some steel wire i picked up at ACE. Holy crap that stuff was hard to bend. And I wore out a pair of Diagonal Cutters too. My hand is going to be sore tomorrow.

In order to actuate the arm, I had to attach the servo horns somehow. I made servo links from some steel wire i picked up at ACE. Holy crap that stuff was hard to bend. And I wore out a pair of Diagonal Cutters too. My hand is going to be sore tomorrow. Getting the wire to couple with the erector set was a challenge too. but i found a way to wrap the wire into some stock meccano "ring terminals." I had to crimp the terminals down and wrap the wire around the post for stability, but it turned out great. I also used some hefty HS-645MG metal gear servos from Hi-Tec. These servos have phenomenal torque.

Getting the wire to couple with the erector set was a challenge too. but i found a way to wrap the wire into some stock meccano "ring terminals." I had to crimp the terminals down and wrap the wire around the post for stability, but it turned out great. I also used some hefty HS-645MG metal gear servos from Hi-Tec. These servos have phenomenal torque.

Probably the most difficult part in designing the arm was figuring out how I'd get the wrist to actuate. The shoulder and elbow were tough, but nothing comparted to the wrist. I must have built 10 different claw configurations, and each one wouldn't work for a different reason. Some weren't stable enough, some couldn't hook up to the servos, some were too heavy, too weak, etc. Finally I came up with the design you see here. I think it's perfect, and it balances well with the rear end of the wrist.

You can see that I used the stock Meccano rubber pads for gripping on the claw.

It's important when working with hobby servos, not to stress the servo horn radially. This can damage the axle of the servo, particularly with the wimpy HS-325HB servos I would be using at the wrist. These servos have "karbonite" inner gears. These gears are tougher than plastic, but don't have the durablilty to withstand much abuse. They're kind of like a nylon material. I decided I'd mount the wrist tilt using dual servos facing inward toward the wrist. This would ensure that there was only a low radial load.

It's important when working with hobby servos, not to stress the servo horn radially. This can damage the axle of the servo, particularly with the wimpy HS-325HB servos I would be using at the wrist. These servos have "karbonite" inner gears. These gears are tougher than plastic, but don't have the durablilty to withstand much abuse. They're kind of like a nylon material. I decided I'd mount the wrist tilt using dual servos facing inward toward the wrist. This would ensure that there was only a low radial load. Adding the wrist rotation was even more difficult. I wanted to get at least 520 degrees of rotation for manipulating small objects, but servos only have about 190 degrees at most. I used some stock Meccano gearing and built a servo bracket to mount a drive gear vertically: The smaller gear at the bottom is on a shaft that the claw is bracketed to, making the shaft and claw rotate perfectly. (Sounds easy when it's right in front of you, but this took days to figure out)

Adding the wrist rotation was even more difficult. I wanted to get at least 520 degrees of rotation for manipulating small objects, but servos only have about 190 degrees at most. I used some stock Meccano gearing and built a servo bracket to mount a drive gear vertically: The smaller gear at the bottom is on a shaft that the claw is bracketed to, making the shaft and claw rotate perfectly. (Sounds easy when it's right in front of you, but this took days to figure out)

Below a shot of the pinchers i tried to use. (Grabber attempt #7). I used Shapelock, which is a great product for prototyping. Unfortunately they turned out to be too flexible for my liking. Plus they went against my goal of a pure meccano build.

Below a shot of the pinchers i tried to use. (Grabber attempt #7). I used Shapelock, which is a great product for prototyping. Unfortunately they turned out to be too flexible for my liking. Plus they went against my goal of a pure meccano build. Shapelock is a low temperature thermoplastic that can be reheated and reshaped endlessly. It's like modeling clay, but better! Given the correct thickness, they would have been less flexible, but I didn't want to worry about the weight etc.

Shapelock is a low temperature thermoplastic that can be reheated and reshaped endlessly. It's like modeling clay, but better! Given the correct thickness, they would have been less flexible, but I didn't want to worry about the weight etc.Sunday, January 18, 2009

Electronics and Meccano (Erector)

Arduino and Lithium Backpack from http://www.liquidware.com/.

Arduino and Lithium Backpack from http://www.liquidware.com/.

But just what is this that I'm attaching the servos to?